A castor product how to have a market, want to be able to be accepted by everyone, then you have to meet the needs of customers, when you produce castor products just can solve the problems it is now facing. Even if you do not advertise there will be a continuous crowd to buy from you, so we do castor products should be done to meet customer needs, rather than to do products. So let's talk about casters from the basic processing.

Before castor production, lubricating oil is added to each lubricating point of the lathe, and the lathe is idled for 3-5 minutes to check whether the lathe is abnormal.

The lathe is normal, the dial indicator is used to measure the lathe chuck, confirm that the chuck meets the quality requirements and standards, select the right casting model, casting requirements, no oil trace, missing material gap, trachoma, holes, broken bars, inner holes with iron, rust.

When processing castings, it is necessary to be close to the root of the chuck, and there is no gap between the jaws and the castings. Attention should be paid to the grip, the hole and the surface of the castings can not be processed twice, and the swing of the castings can be scrapped after secondary processing.

When placing castings, step on the foot switch, press the chuck root, loosen the foot switch, press the work button, lathe rotation completely stopped, step on the foot switch, in order to remove the casting, into the next process. If casting must be often sharpened.

Put and take parts should be handled gently and placed according to regulations, so as to avoid material leakage when hanging PU materials caused by collision. Defects caused by casting and machining reasons should be placed in the designated area and cleaned on the same day.

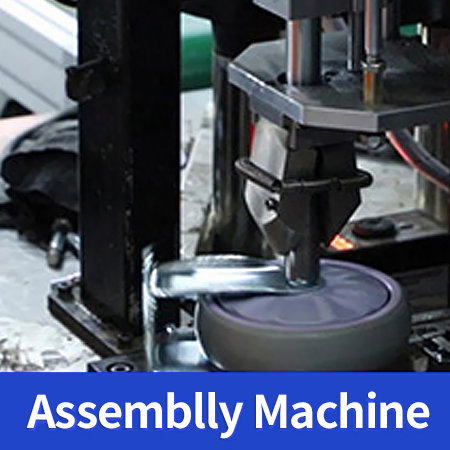

When the casters are processed in the workshop, the drawings are carefully checked first, and then the products are processed. The machine tool equipment used in the processing of casters is an important way to ensure the quality of casters after processing, so regular and long-term maintenance of machine tool equipment is the daily work that every caster processor should do.

Huizhou Jianli Hardware Casters Co., Ltd

Huizhou Jianli Hardware Casters Co., Ltd