How to choose the right castor for your use?

1. How to choose the proper wheel

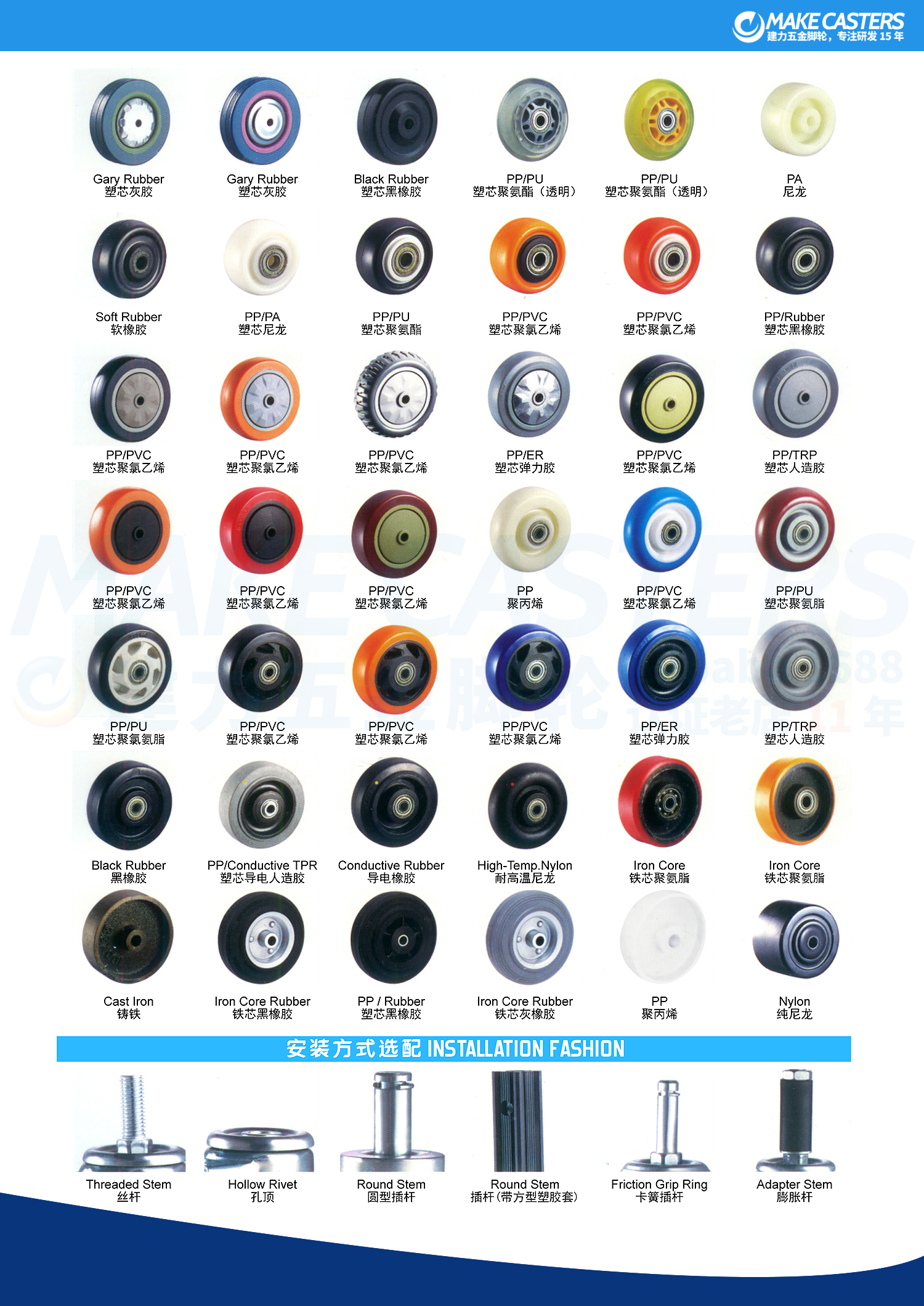

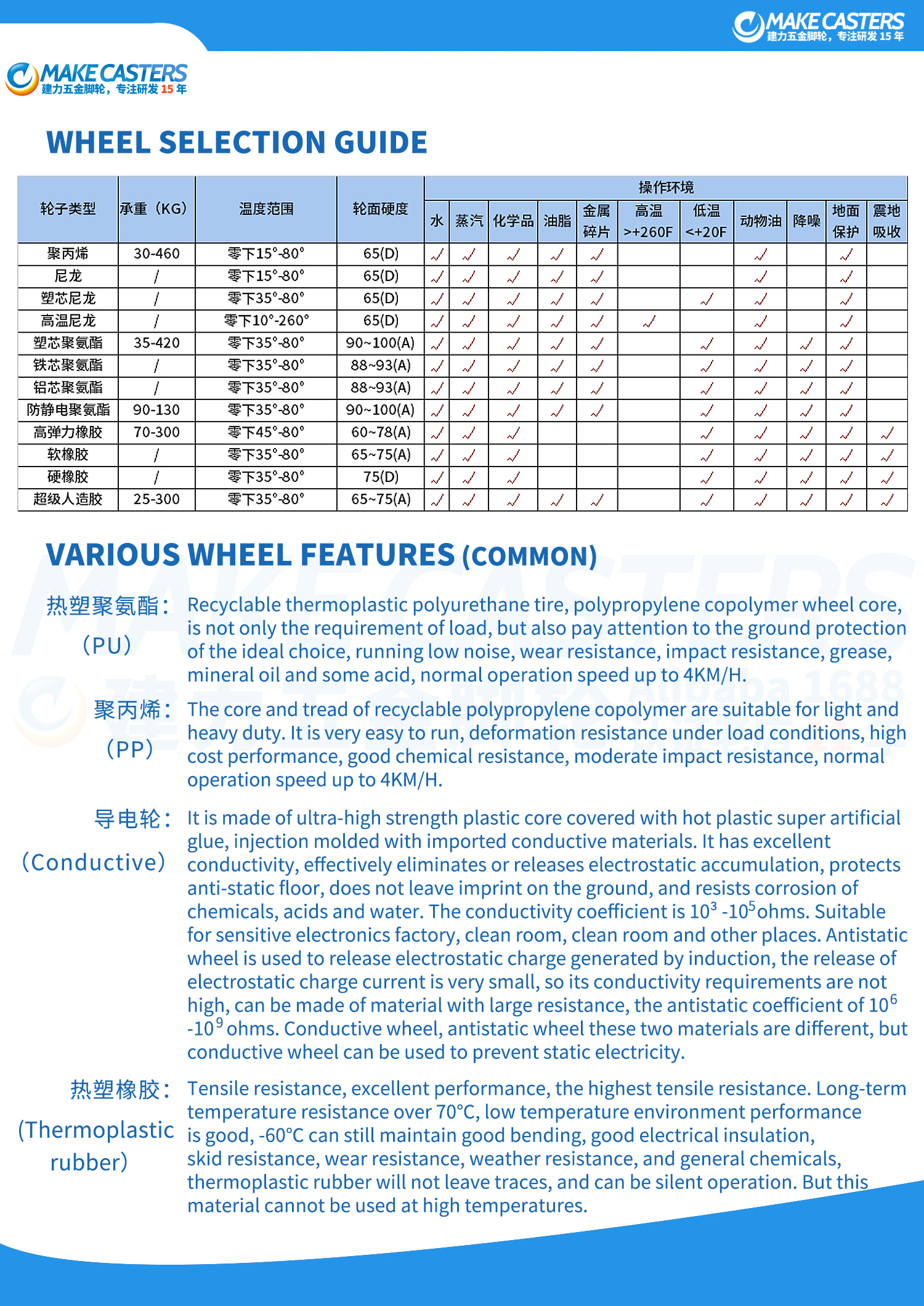

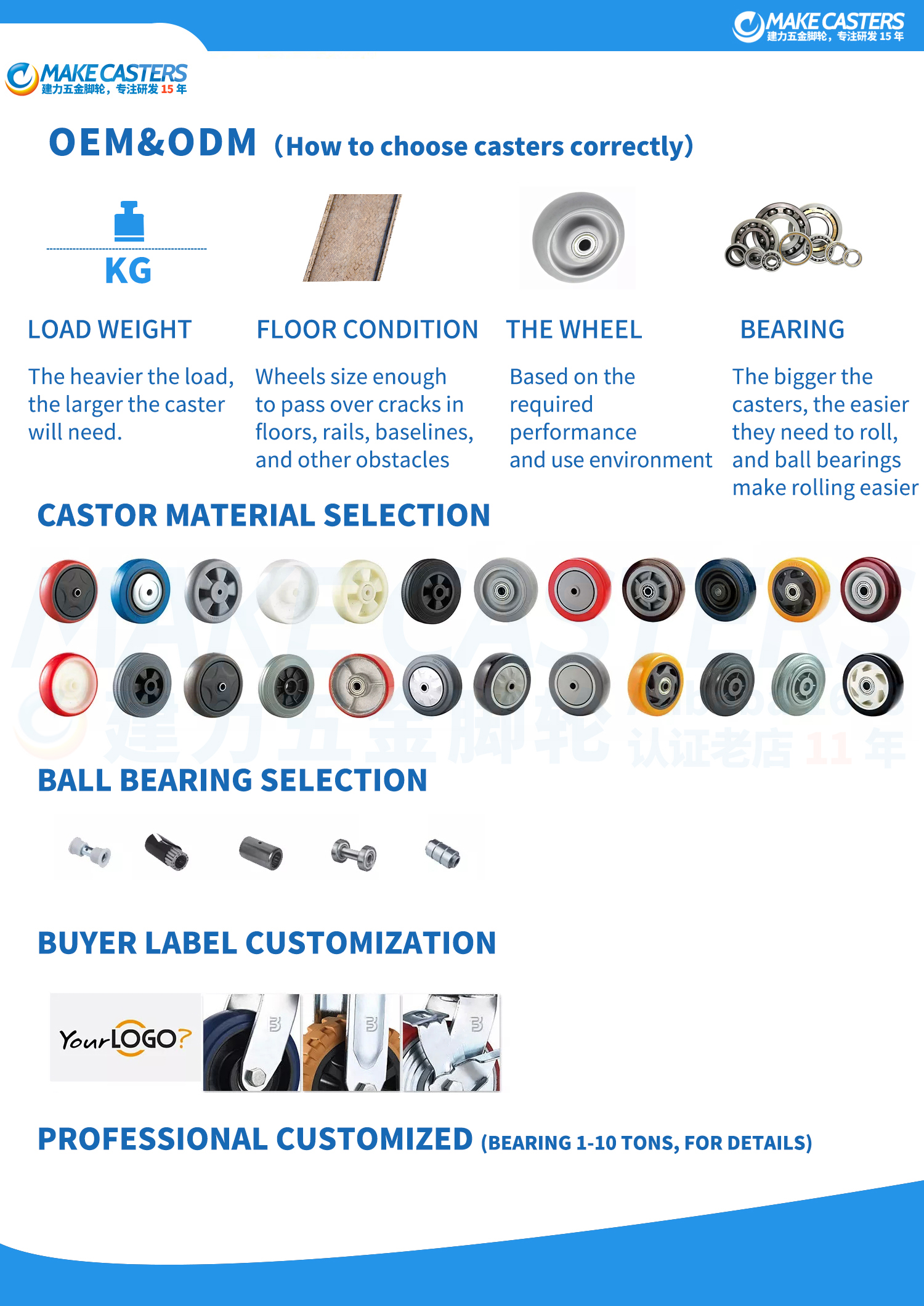

1) Choice of wheel material: first of all, consider the size of the road surface, obstacles, the use of residual materials on the site (such as iron, grease), the environmental conditions (such as high temperature, normal temperature or low temperature) and the weight of the wheel can bear different conditions to decide the choice of suitable wheel material. For example, rubber wheels are not resistant to acids, oils and chemicals, while super polyurethane wheels, high strength polyurethane wheels, nylon wheels, steel wheels and high temperature wheels are suitable for different special environments.

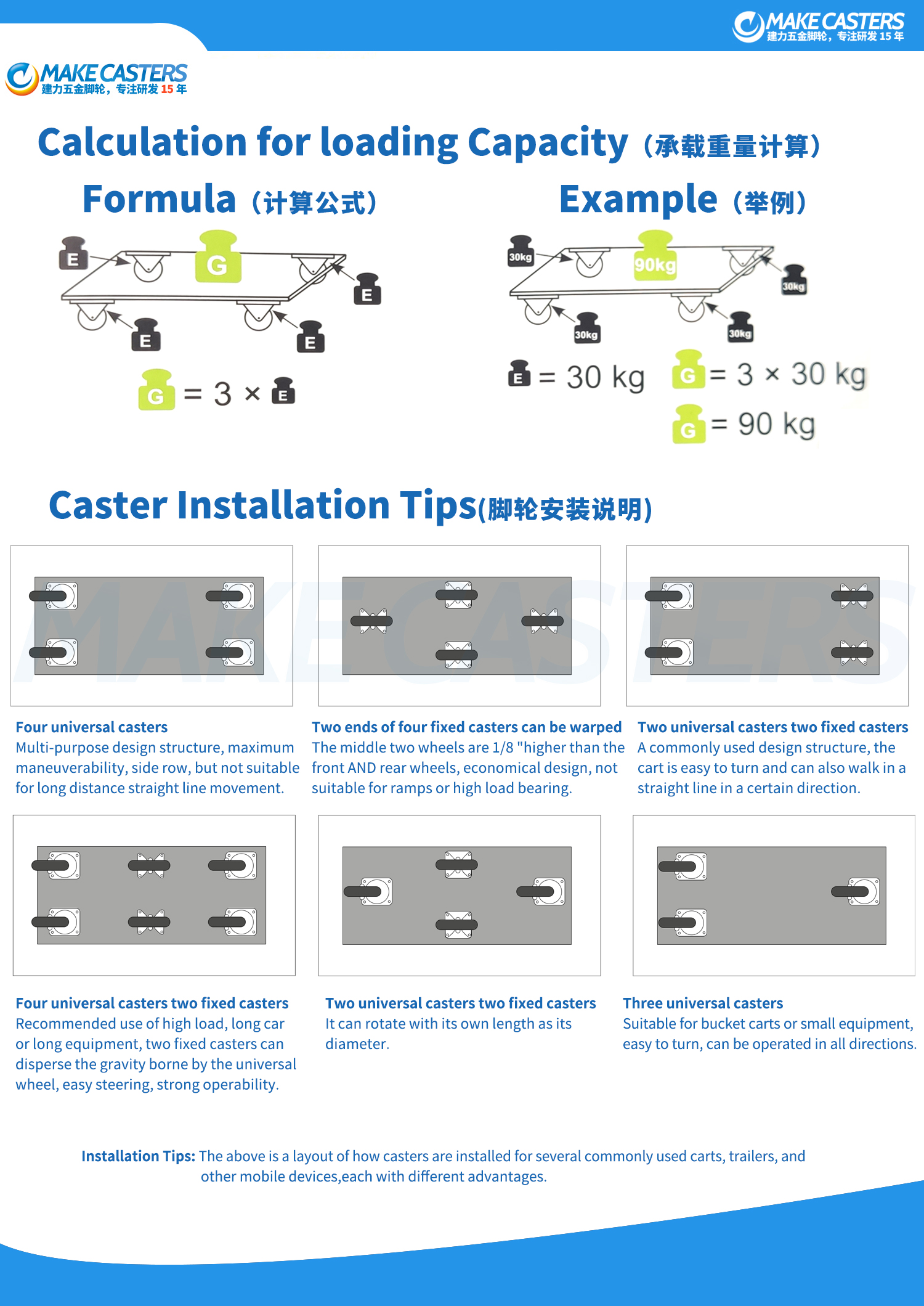

2) Calculate the load weight: in order to be able to calculate the load capacity required by various casters, it is necessary to know the dead weight of the transport equipment, the maximum load and the number of single wheels and casters used. The load capacity required for a single wheel or caster is calculated as follows:

T = (E + Z)/M (N:

--T= the weight of a single wheel or castor;

--E= dead weight of transport equipment;

- Z = * load;

--M= number of single wheels and casters used;

--N= safety factor (about 1.3 -- 1.5).

3) determine the size of the wheel diameter: usually the larger the wheel diameter, the easier it is to push, the larger the load capacity is and the better it can protect the ground from damage. The choice of the wheel diameter should first consider the weight of the bearing load and the starting thrust of the truck under the load to determine.

4) The choice of wheel material soft and hard: usually the wheel has nylon wheel, super polyurethane wheel, high strength polyurethane wheel, high strength artificial rubber wheel, iron wheel, air wheel. Super polyurethane wheel, high strength polyurethane wheel can meet your handling requirements regardless of indoor and outdoor ground driving; The high strength artificial rubber wheel can be used in hotels, medical equipment, floors, wooden floors, ceramic tile ground and other requirements of walking on the quiet ground with small noise; Nylon wheel, iron wheel is suitable for uneven ground or ground with iron filings and other materials of the site; The air pump wheel is suitable for light load and soft uneven road occasions.

5) Rotational flexibility: the larger the single wheel, the more energy saving, roller bearing can carry heavier load, greater resistance when rotating: the single wheel installed with high quality (bearing steel) ball bearings, can bear heavier load, rotation is more light, flexible and quiet.

6) Temperature condition: cold and high temperature occasions have a great impact on the caster, polyurethane wheel at minus 45℃ low temperature, flexible rotation, high temperature resistant wheel at high temperature 275℃ light rotation.

2. How to select the appropriate stent

1) choose a suitable wheel rack first consider the weight of the caster wheel bearing such as supermarkets, schools, hospitals, office buildings, hotels and other places, because the floor is good, the smooth handling of the goods is lighter, (each trundle bearing in 10-140 - kg), suitable for selection (2-4 mm) with a thin plate stamping plating wheel frame, the wheel frame is light, flexible operation, quiet and beautiful, The plating wheel frame is divided into two rows of beads and single row of beads according to the ball arrangement. If often moving or handling, use a double row of beads.

2) In factories and warehouses and other places, the cargo handling is very frequent and heavy load (each caster bearing 280-420kg) is suitable for the selection of thick steel plate (5-6 mm) stamping hot forging and welding of double row ball bearing wheel frame.

3) if used for carrying heavy things such as textile factory, automobile factory, machinery factory and other places, because the charge big factories within walking distance (caster wheel bearing only at 350-1200 kg) each, therefore, should choose (8-12 mm) with a thick plate after cutting wheel frame, welding activities wheel rack flat ball bearing and ball bearing on the floor, make the castor can withstand the heavy loading, Flexible rotation, anti-impact and other functions.

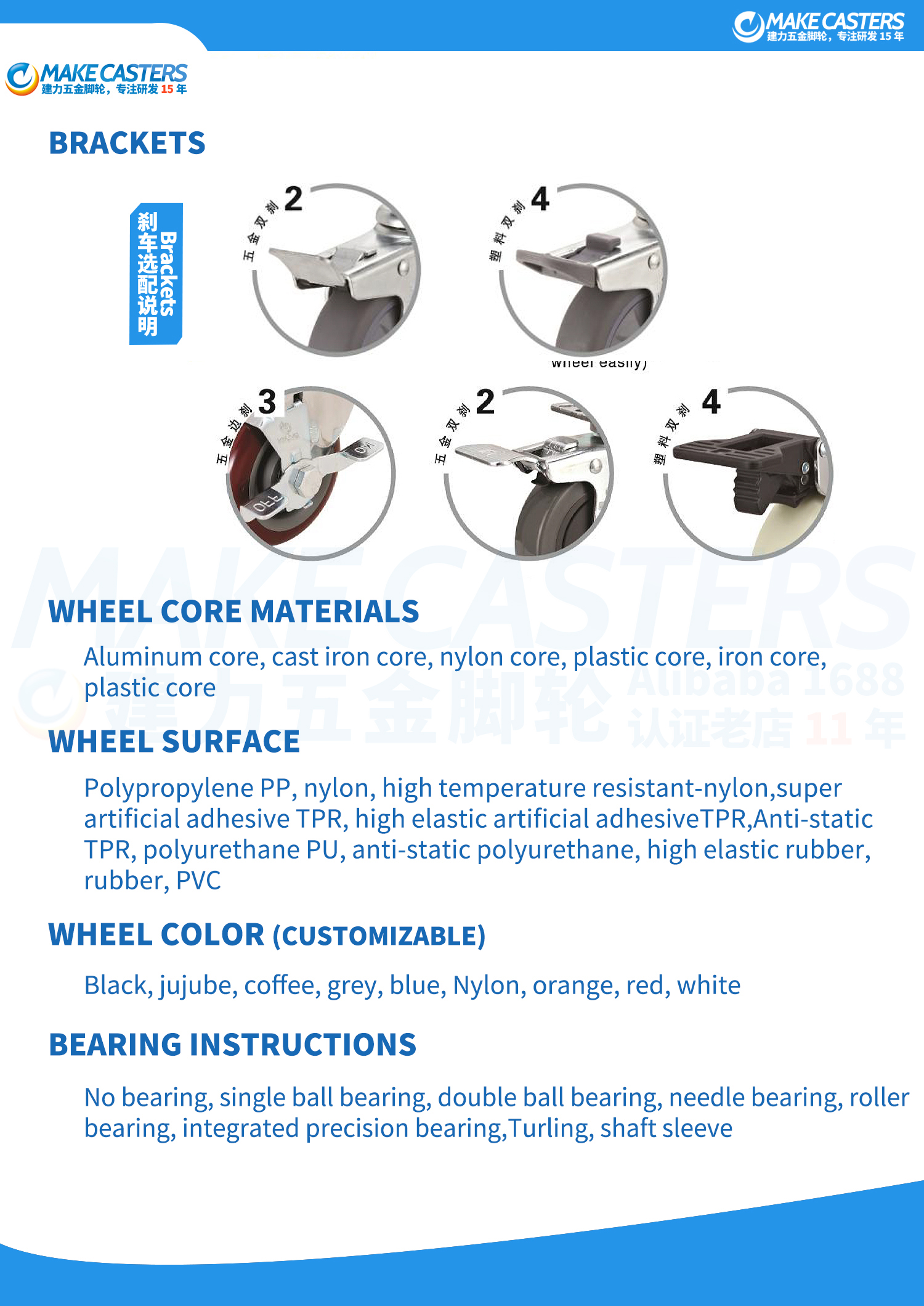

3. choose the right bearings

1) Turling bearing: Turling is a special engineering plastic, suitable for wet and corrosive places, the flexibility of rotation is general, and the resistance is large.

2) Roller bearing: after heat treatment, roller bearing can bear heavy load and has general rotation flexibility.

3) Ball bearings: Ball bearings made of high quality bearing steel can bear heavy loads and are suitable for occasions requiring flexible and quiet rotation.

4) Plane bearing: suitable for high and extra high load and high speed occasions.

4. material

Polyurethane, cast iron steel, nitrile butadiene rubber rubber wheel (NBR), nitrile butadiene rubber rubber wheel, natural rubber wheel, silicone fluorine rubber wheel, neoprene rubber wheel, butyl rubber wheel, silicone rubber (SILICOME), EPDM rubber wheel, VITON rubber wheel, hydrogenated nitrile butadiene (HNBR), polyurethane rubber wheel, rubber and rubber, PU rubber wheel, PTFE rubber wheel (PTFE workpiece), nylon gear, polyformaldehyde rubber wheel, PEEK rubber wheel, PA66 gear, POM rubber wheel, engineering plastic parts (such as high strength PPS tube, PEEK tube, etc.).

Huizhou Jianli Hardware Casters Co., Ltd

Huizhou Jianli Hardware Casters Co., Ltd