1. What are casters?

Casters are small wheels mounted under objects to make them easy to carry and transfer.

Castor is a general term, including activity castor and fixed castor, brake castor. Movable casters are also known as universal wheels, whose structure allows 360 degrees of rotation; Fixed casters also called directional casters, it has no rotation structure, can not rotate. Usually two casters are generally used together, such as the structure of the trolley is the front two directional wheels, behind close to push the handrail is two universal wheels. Casters have a variety of materials casters, divided into core material and wheel surface material, such as cast iron wheel, nylon wheel, etc. Widely used in all kinds of carts, dining cars, logistics, instruments and other equipment.

Casters appear to people handling especially moving objects has brought the convenience of The Times, not only can be easily handled, but also can move with any direction, improve work efficiency.

2. castor structure characteristics

⚪ Installation height: refers to the vertical distance from the ground to the installation position of the equipment. The installation height of the caster refers to the vertical distance from the bottom plate of the caster to the edge of the wheel.

⚪ Support steering center distance: refers to the horizontal distance between the center rivet vertical line and the center of the wheel core.

⚪ Radius of rotation: refers to the horizontal distance between the center rivet vertical line and the outer edge of the tire. The appropriate distance allows the caster to turn 360 degrees. Whether the rotation radius is reasonable or not directly affects the service life of casters.

⚪ Driving load: caster bearing capacity is also called dynamic load when moving, castor dynamic load due to different test methods of the factory, but also because of the wheel material is different, the key is whether the structure and quality of the support can resist impact and shock.

⚪ Impact load: the instantaneous bearing capacity of casters when the equipment is impacted or shaken by the load. Static Load Static load Static load: The weight that the castor can bear at rest. Generally, the static load should be 5 ~ 6 times of the exercise load (dynamic load), and the static load should be at least 2 times of the impact load.

⚪ Steering: Hard, narrow wheels are easier to steer than soft, wide wheels. The radius of rotation is an important parameter of wheel rotation. If the radius of rotation is too short, it will increase the difficulty of turning. If the radius of rotation is too large, it will cause the wheel to shake and shorten its life.

⚪ Driving flexibility: The factors that affect the castor driving flexibility are the structure of the support and the selection of steel support, the size of the wheel, the type of the wheel, the bearing, etc. The larger the wheel, the better the driving flexibility. On the smooth ground, the hard and narrow wheel is less effort than the flat edge soft wheel, but on the uneven ground, the soft wheel is less effort. But on uneven ground, soft wheels provide better protection and shock absorbers!

3. Precautions for using casters

⚪ Avoid being overweight.

⚪ Do not bias.

⚪ Regular maintenance, such as regular oiling, timely check the screws.

4. classification

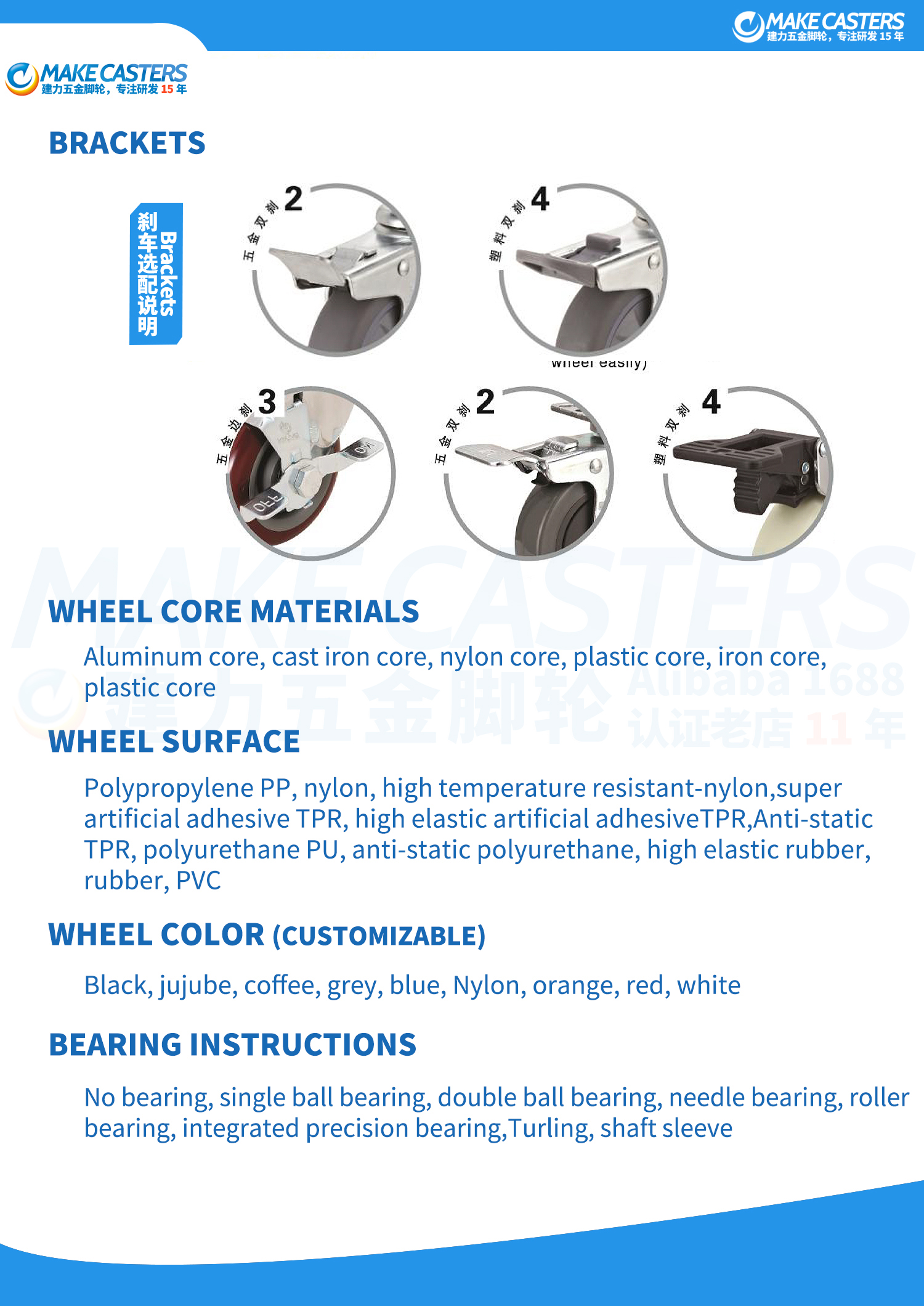

1) According to the steering classification: directional and universal casters, and brake function.

2) By application industry: mainly divided into medical casters, industrial casters, supermarket casters, furniture casters, etc.

⚪ Medical casters are special casters that meet the requirements of hospitals, such as light operation, flexible steering, large elasticity, special ultra-quiet, wear-resistant, anti-winding and chemical corrosion resistance.

⚪ Industrial casters mainly refers to a castor products used in factories or mechanical equipment, it can choose advanced imported reinforced nylon (PA6), super polyurethane, rubber made of a single wheel, the whole product has high impact resistance and strength.

⚪ Supermarket casters for supermarket shelves to adapt to the needs of moving and shopping cart needs light and flexible characteristics of the specially developed casters.

⚪ Furniture casters mainly to adapt to the needs of low center of gravity, high load and production of a special casters.

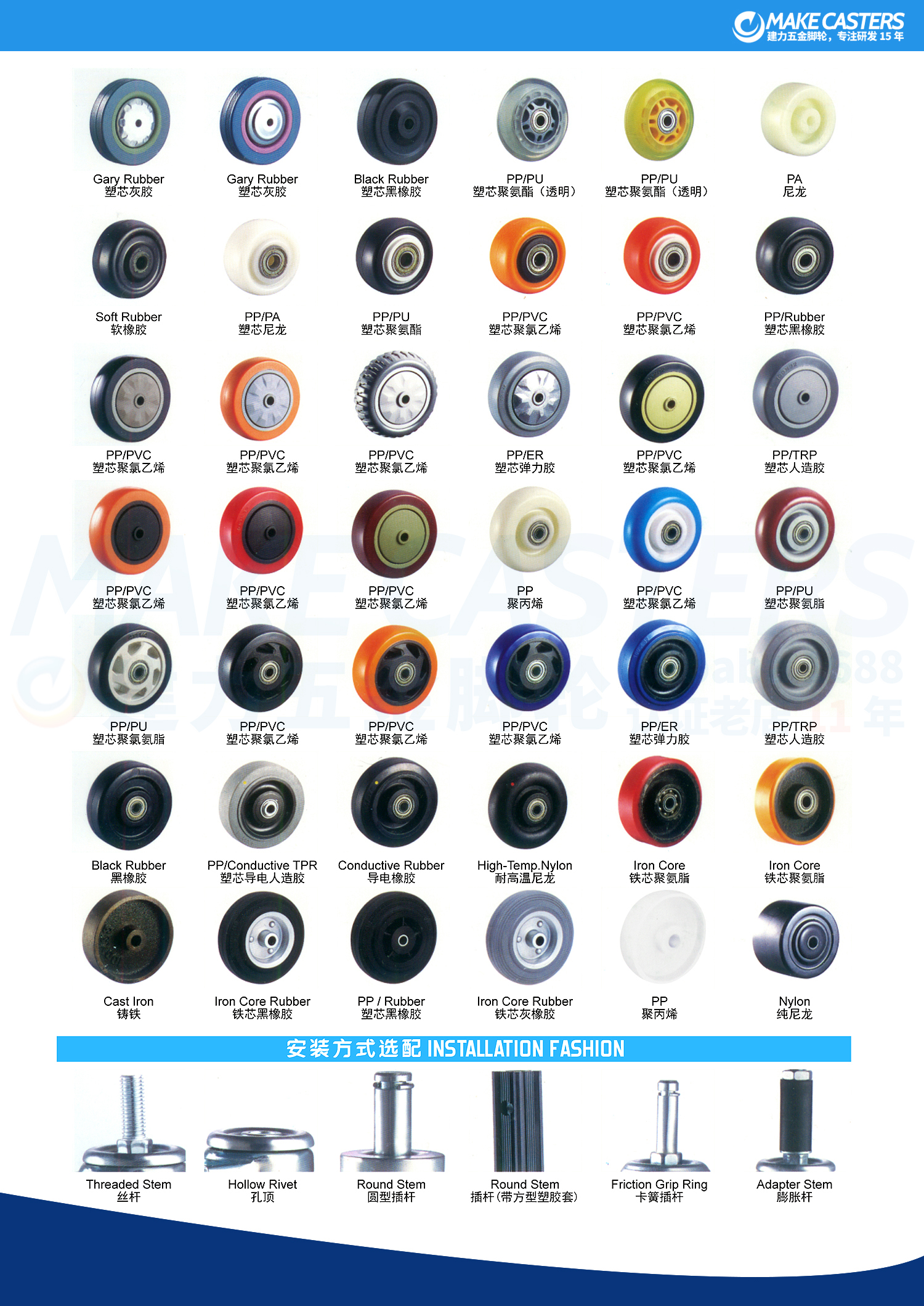

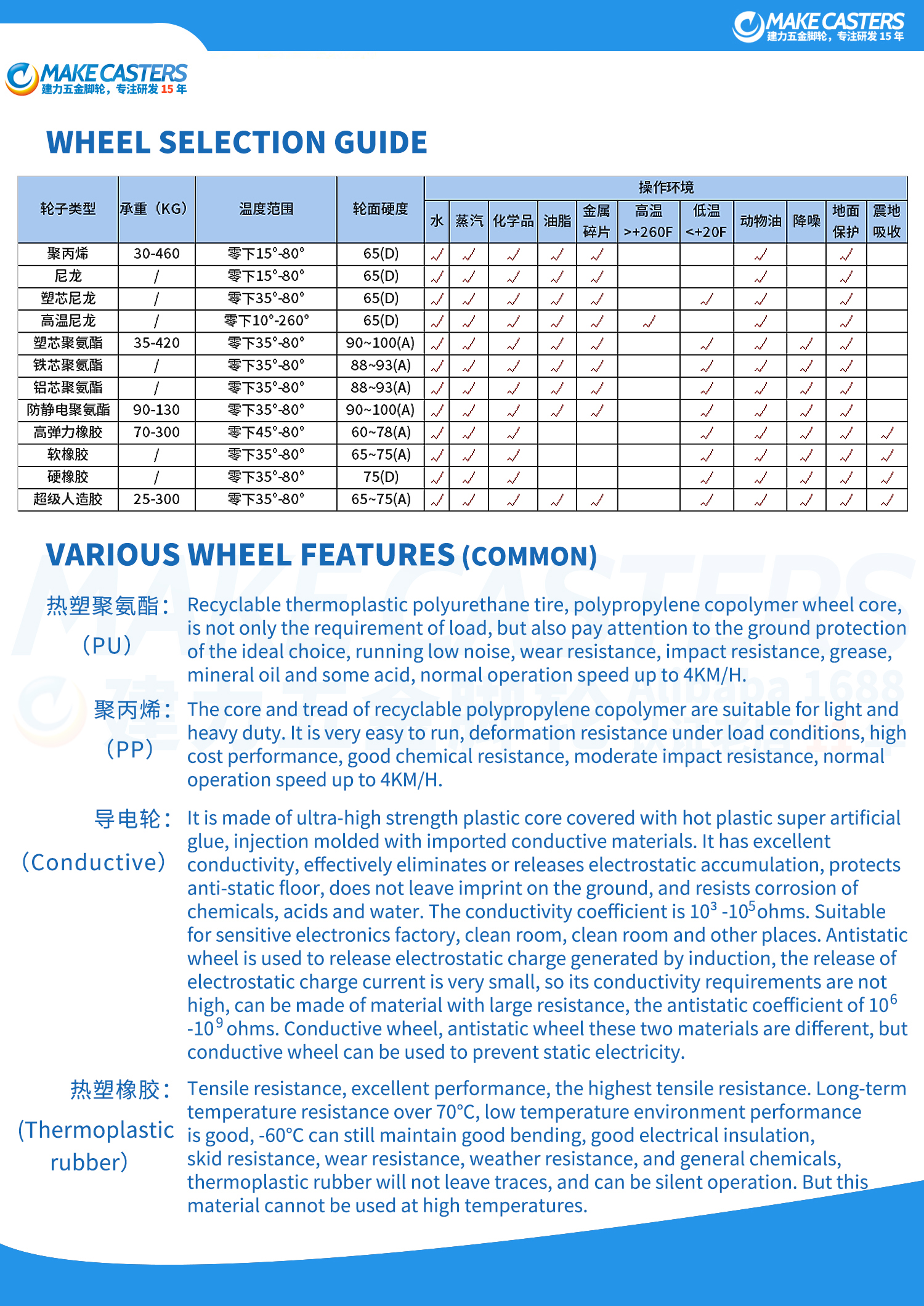

3) Classification according to castor material

It is mainly divided into super artificial rubber casters, polyurethane casters, plastic casters, nylon casters, steel casters, high temperature casters, rubber casters, S-type artificial rubber casters.

5. App editing

Mainly in the trolley, mobile scaffolding, workshop truck and other aspects are extremely extensive.

The simplest inventions are often the most important, and casters have this property. At the same time, the degree of development of a city is often positively correlated with the number of casters used, and the more developed the city's casters are very high.

The casters are constructed of a single wheel mounted on a bracket for mounting under the equipment to allow it to move freely. Casters are mainly divided into two categories:

1. Castor fixing bracket with a single wheel, can only move in a straight line.

2. Movable caster 360-degree steering bracket is equipped with a single wheel, which can drive in any direction at will.

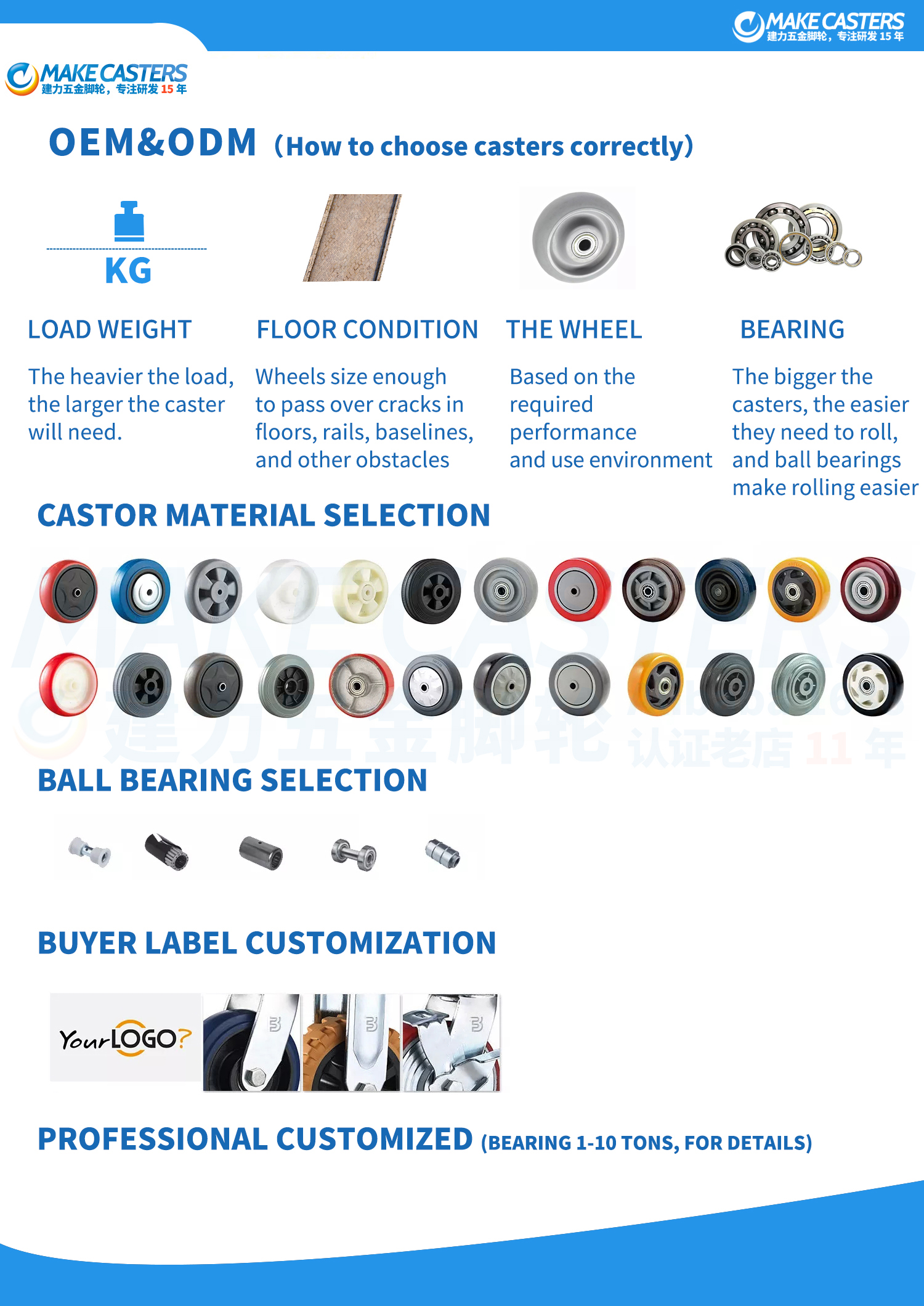

Industrial casters have a wide variety of single wheels, in size, model, tire tread and so on. The selection of a suitable wheel depends on the following conditions:

1. Use the site environment.

2. The deadweight of the product

3. The working environment contains chemicals, blood, grease, oil, salt and other substances.

4. All kinds of special climate, such as humidity, high temperature or cold E impact resistance, collision and driving quiet requirements.

Huizhou Jianli Hardware Casters Co., Ltd

Huizhou Jianli Hardware Casters Co., Ltd